Our different courses in detail

Full House Bladesmithing – 5 day courseMaximum 3 students |R11 500 per person |Deposit: R2 000|All skill levelsOur most popular course. For those wanting to cover the most comprehensive course in forging knives and damascus in the shortest space of time. This course covers all that you would learn on the Basic Bladesmithing course as well as the Introduction to Damascus course at a much-reduced price: you save R1 750 per person by doing the Full House 5-day course as opposed to doing two courses separately. You will make a carbon steel knife and sheath worth over R3 000 and a damascus steel blade worth over R4 000. Not suitable for people who are allergic to nickel. | |

Basic Bladesmithing – 3 day courseMaximum 4 students |R7 000 per person |Deposit: R2 000|All skill levelsBladesmithing is the historical and traditional way of knifemaking by bladesmiths using high carbon steels. Utilizing hammer, fire and anvil a knife will be made proceeding from design, forging, heat-treatment, grinding, polishing, handle, leather sheath making and sharpening. You will come away with your own hand-forged knife and sheath as well as the knowledge to make more. (The bug will have bitten!). You do not have to be big and brawny to do this course! You will make a knife that is worth more than R3 000 on this course. | |

American Bladesmith Society Approved Intro to Bladesmithing – 2 week courseMaximum 6 students |R18 500 per person |Deposit: R2 000|All skill levelsFor anyone, beginner or advanced, who is serious about their Bladesmithing. Particularly important for ABS Apprentice Smiths wishing to submit their knives for ABS Journeyman Smith evaluation, as attending the course, cuts one year off their three-year apprenticeship. Great course for stock removers who want to branch out into forging knives. Recognised by the American Bladesmith Society, this course is presented by two ABS Master Bladesmiths, husband and wife team, Kevin and Heather Harvey. There are nine ABS recognised schools in the world. Seven ABS schools are in the U.S.A, one in Belgium and Heavin Forge in South Africa. This is an intensive two week, eighty-hour, hands-on course which covers all aspects of forging, grinding, heat treating and sharpening blades. One blade will be used to do the (unofficial) ABS Journeyman performance (cut and bend) test at the end of the course. This test is also required if submitting forged blades for evaluation to gain entry into the Knifemakers’ Guild of Southern Africa. If you wish to do the test for the KGSA or ABS you will need to do this with us at a later stage with a knife that you have made entirely by yourself. Kevin and Heather have taught this Introduction to Bladesmithing course a number of times at the Bill Moran School of Bladesmithing in Old Washington, Arkansas, U.S.A. They endeavour to impart their knowledge and love of the forged blade to their students. Numerous different forged blade shapes are taught to educate the students as to the many varied ways of forging, heat treating and grinding. We try to finish 3 to 5 blades to a point where they can easily be finished at home after the course and sold. The sale of these knives should easily cover your course fee. Lectures are given each day on subjects covering how to select your steel, designing knives, safety in the workshop, the safe use of gas forges, blade geometry, heat treatment, grinding, hand finishing, filing, forging unusual shaped knives/weapons, forging other metals, the business side of knifemaking, the ABS and KGSA testing and much more. “Please note that this course, whether done here or overseas, does not cover handles, fittings, sheaths nor the making of Damascus steel.” Time does not permit this on the two-week course. We offer separate courses to cover these subjects, namely “Handles, Fittings and Sheaths” which is always presented the week after the ABS course and “Intro to Damascus” which is presented on the week after the “Handles” class and lasts 3-days. We offer a 10% discount to students that book to do all three courses. By doing these courses, you will have a very solid grounding to carry on bladesmithing either as a hobby or full-time (obviously with a lot of practice!). Evenings will be spent watching ABS forging DVD’s. Each student is entitled to take home his finished blades to complete at home. This course does not cover handles, guards and sheaths, for this reason, we suggest students stay on for the 5-day Handles, Fittings and Sheaths course often held the week after the ABS course. A certificate will be issued at the end of the course. Kevin and Heather have a vast library of knifemaking/Bladesmithing/blacksmithing books and videos which can be read/viewed while on course. Comprehensive notes, and Heavin’s book, “How to Make a Narrow Tang Knife” are provided as well as a denim apron, safety glasses, leather gloves, a simple face mask, tin of Harveys Conservation Paste and all consumables. Tea, coffee, cool drinks and biscuits/rusks are provided. If you are here by car and stay the weekend, we can help organise a few fun activities in the region in the area such as whisky tasting, a visit to our micro-brewery in Dullstroom – Anvil Ale, fly-fishing, horse riding, clay-pigeon shooting, archery, hiking or game viewing. If you are coming from overseas, we strongly suggest that you include a holiday to the Kruger National Park, just three hours away from us as well as sightseeing in the area along the “Panorama Route”, just two hours away from us. If you wish to plan a safari please contact us and we can put you in contact with the right people. | |

Look and Learn (on demand) – 1 dayMaximum 4 to 8 students | R1 000 per person | Deposit: R500| Open to all levelsA course very popular with collectors and other people interested in seeing if they might enjoy taking up the hobby. Follow the process of a knife being made using either the stock removal or forging method from start to finish in one day. A full tang knife is made in front of a group not exceeding eight in number. Follow the method used, take notes, ask questions and learn. Lunch and refreshments are provided. Starting time: 8 am – finishing at approximately 5 pm If you wish to do this course, please contact us, as it is not a scheduled course and can be done on almost any day that suits everyone. | |

Handles, Fittings and Sheaths – 5 daysMaximum 6 students | R10 500 per person | Deposit: R2 000| Experience requiredYou have to have completed one of our other courses first or be an accomplished stock remover knifemaker. This course offers you the chance to learn how to fit handles, guards and bolsters to your blades as well as how to make a sheath. We find that a lot of our students either don’t have the facilities or know-how to complete their knives once home, especially the students from our 2-week ABS course who have only made blades, no handles and sheaths, as done on our other courses. Lectures will include handle construction and design, stabilizing bone and wood, finishing handles with gunstock oils etc. You are required to bring one or two finished blades with you, either made at home or on a previous course with us as well as your handle, guard/bolster and pinning materials if using anything other than standard wood, brass and nickel silver, which will be provided. Some limited fancier materials will be available here to purchase. We will supply basic sheath leather but any exotic leathers must be brought with you. The projects tackled by each participant might be different and we feel those attending will learn from each other too. We offer a 10% discount to students who book to do this course along with the ABS Intro to Bladesmithing Course and the Intro to Damascus course. | |

Special Project Course: Bowie Build – 4 daysMaximum 3 students / R9 500 per person / Deposit R2 000 / Experience requiredThis 4-day course offers the student who has already done a previous course with us, an opportunity to refine his/her skills with regards to the making of a Bowie knife and sheath. Kevin’s favourite knife is the Bowie knife and he has a passion for them. You will learn about the history of the Bowie knife and learn the “Kevin’s Bowie Rules” with regard to the shape and balance which makes for a good Bowie knife. You will leave with a forged carbon steel Bowie knife and sheath and the inspiration to make more of them! | |

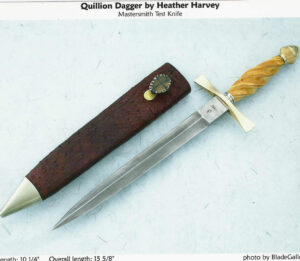

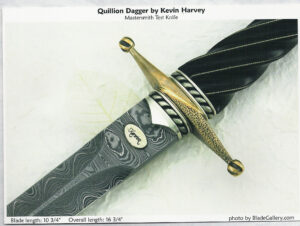

Special Project Course: Dagger Build – 5 daysMaximum 3 students / R10 700 per person / Deposit R2 000 / previous Heavin Forge students onlyA “Special Project Course” available to past students of ours. In 5 days you will make a Quillion dagger with fluted, wire inlaid handle. You can either bring your own Damascus blade (there will be no time on this course to forge a Damascus blade), forged to profile (no bevels) or forge a carbon steel blade on course. This course will prepare you for your Mastersmith submission where a damascus European Quillion dagger is one of the knives you need to submit. Here a link to the requirements to pass your M.S evaluation http://americanbladesmith.com/uploads/file/Testing/MS_Test_FINAL_11-04-2019.pdf This course will give you an understanding of what is required however you will not be allowed to submit the dagger you make on course as you have to have made the dagger by yourself, without any supervision. | |

Special Project Course: Advanced Damascus Chef Knife – 4 daysMaximum 3 students / R9 500 per person / Deposit R2 000 / previous Heavin Forge students onlyA “Special Project Course” available to past students of ours. In 4 days you will make a San-Mai style chef knife which consists of a hard steel core and Damascus sides. You will learn about the various different European and Japanese chef knives and different handle constructions. No sheath done on this course. | |

Introduction to Damascus Steel Making – 3 daysMaximum 3 students | R8 300 per person | Deposit: R2 000| Experience requiredYou have to have completed the Basic Bladesmithing or ABS Intro to Bladesmithing course with us as the fundamentals of forging and heat-treating high carbon steels are covered in it, and this experience is required for making a damascus knife. Alternatively, you can join the 5 Day Full House Bladesmithing Course, which combines the Basic Bladesmithing with the Introduction to Damascus Course at a reduced course fee. This course includes material selection, preparation, lamination (forge-welding), patterning, forging to knife shape, grinding, heat-treatment, polishing and etching. The knife is completed to a stage where the maker can fit a handle at a later stage or an integral knife is made. Handle and sheath making was covered in the previous Intro to Bladesmithing course. Work is done using a high-temperature gas forge and the “Iron Maiden” power hammer. You come away from this course (hot and sweaty!) with the knowledge of making basic traditional folded damascus steel and how to turn it into a stunning blade. You will make a damascus steel blade on this course that is worth more than R4 000. Not suitable for people who are allergic to nickel. This course is always scheduled after the 2-week ABS Intro to Bladesmithing Course, followed by the Handles, Fittings and Sheaths course. A 10% discount is offered to students attending all three courses. What is Damascus steel ? – Over 2000 years ago man needed to create a strong steel. This he did by forge-welding and folding high and low carbon steels at high temperatures to create a steel that was flexible but hard enough to hold an edge. The pattern in the steel can be manipulated and is brought out by etching the steel in acid. Damascus steel was perfected by the Japanese and Vikings and it was believed to have magical properties. There are very few bladesmiths who make their own damascus steel these days and it is a rare and collectable material usually used for knife blades. |